Battery Bank Sizing and Pylontech’s Active BMS

When designing a power system, people usually ask two key questions: 'What is the performance?' and 'How much will it cost?'

How do you balance cost and performance? The battery bank, it turns out, plays a more crucial role in achieving that balance than any other factor in these systems. This article will help you understand how battery size relates to performance, giving you a clearer perspective for making an informed purchasing decision.

Load Considerations

To begin with, let's clarify the two factors at play when drawing power from a battery: Watts, and Watt-hours. Watts is the measurement of power being instantaneously consumed. Watt-hours is a true energy measurement because it’s specific to a period of time.

Reminder: A 60-watt light bulb will draw 60 watts continuously over the course of an hour, consuming a total of 120 watt-hours after two hours of use (60 watts x 2 hours = 120 watt-hours). For a battery bank to supply this load, the battery must be capable of supplying 60W of continuous power and have sufficient capacity to sustain that output for 2 hours.

While powering a light bulb is straightforward, managing well pumps and larger electrical loads requires careful consideration of the battery bank's capacity. For example, a 3/4 horsepower well pump running for 6 minutes per hour draws 1,310 watts during operation, consuming 131 watt-hours (Wh) in total.

When powering such a pump, the battery bank's limitation isn't just its total stored energy in watt-hours—it's the battery's capacity to deliver instantaneous power in watts. Understanding this requires us to examine what's happening at the battery-level, particularly the current draw in a 48V battery system.

Peak Demand

When discussing battery performance specifications, the main point of interest is the maximum current rating for the battery. To calculate this value in our scenario, we use the formula: 1,310 W divided by the battery voltage, which is a nominal 48V. This gives us a current of approximately 27A, a modest load for your average battery. The kicker is, electric motors, such as traditional well pumps, require a significant surge of power when starting up.

Referring to the Locked Rotor Amps (LRA) for a 230V motor on this chart (Full PDF), we see that for a ¾ hp traditional well pump, the LRA is 34.2A. That’s 7,766W, which means that our during start up, the current draw from the batteries briefly spikes up to 163A. Designing your system to accommodate peak power demand is crucial for reliable operation. While people tend to focus on inverter size, the cables, fuses, and batteries can all become the weak link during these peak power moments.

Larger battery banks provide a greater operational range and take these peaks in stride. 'Will it work?' is not always the right question; 'How well will it work long-term?' is the thing to consider if you are in the business of making customers happy. A correctly-sized system must be able to handle the above scenario while simultaneously providing power to your microwave, fridge, AC unit and whatever else is added as the system ages.

Battery Capacity Calculation

Often battery power delivery and storage capacity are measured in terms of amperes. You will commonly encounter a 200Ah battery or see potential for power delivery listed as 100A. The principal equation here is Amps × Volts = Watts, so we can convert between amps and watts with some simple math (12,000W ÷ 48V = 250A). You can do the same math for batteries rated in amp hours (200Ah battery bank × 48V = 9600Wh of total power).

Responsible Battery Sizing

Now that we know the difference between a battery's power delivery and power storage, it's time to consider how these factors affect decisions around sizing a battery bank.

Regarding power delivery, let's first remember that batteries are not like generators. If you oversize a generator to your load output, all that you gain is fuel inefficiency and potentially excess wear. Lithium batteries, on the other hand, only benefit as the bank size increases since each unit now has less load. A 100A load will work each individual battery in a 5-battery bank twice as hard as the same load on a 10-battery bank. The less work a battery has to do to deliver power, the longer its lifespan will be, the less it will heat up, and the more efficiently it will deliver that power.

Next, let's make sure we clarify the importance of battery storage capacity. Loads can vary dramatically in an average house with some patterns around the occupants, but they are variable and not predictable. In fact, if you're relying on PV input to help recharge your battery bank, the average household experiences peak power demand in the evening when everyone is back home, all your appliances are running, and the sun is disappearing below the horizon.

A typical off-grid solar scenario illustrates the importance of storage: during peak sunlight hours when energy from the sun is most available, the batteries are charging because the loads are the lowest.

If your primary goal is to avoid running a generator to supplement your power usage, at minimum, your batteries need to be sized to get you through to the next day when the sun comes up. Even this is just the bare minimum. Cloudy days are a reality, fuel is expensive, and ideally, a power system should be able to store several days' worth of electricity so that the sunny days can compensate for the cloudy days when consumption outpaces production.

In this way, your battery bank acts like a suspension coil, smoothing out the bumpy ride of solar power. Whenever the dip in production creates too much variance for your battery bank to absorb, your only options are to run a generator or to go buy a generator.

The Complete Battery System

That's the nutshell argument for oversizing your battery bank to your daily needs. So far, these reasons have been generally applicable regardless of what brand or battery chemistry you decide to go with.

If you are familiar with our preference for Pylontech's high-performance lithium batteries, you probably expect that there is a bit more to the story when using a Pelio or any of the other Pylontech offerings. And you would be correct.

Pylontech batteries offer a tremendous advantage over other lithium batteries when oversizing a bank due to their unique internal Battery Management System. This BMS is present inside each battery and combines complex programming parameters with controllable MOSFETs, which are connected to every single cell within the batteries.

When connected in a communications string, not only does each battery control its individual charge/discharge state, but the master battery keeps a watchful eye over all the follower units and requests a total charge current or allows a total discharge current to match.

Paired with a Victron system running DVCC, the rest of the power components can adjust to provide the batteries with exactly what they need. If a battery bank is like a suspension system for your power, this high-level functionality is a suspension system for that suspension system.

It is impossible outside of a million-dollar lab to keep conditions exactly the same for each battery in a stack. Differing internal resistance, wire length, or temperature can all cause a battery to charge or discharge a little slower or faster than its mates. When this happens, the Master BMS is there to slow things down and let everyone catch up before an issue is even apparent to the end user.

In this way, Pylontech's BMS can control an entire bank of batteries, viewing it not just as a single system but as individual units within the system. It identifies the needs of each unit and allows flexibility within the system to meet the specific needs of each battery, rather than running some units beyond their capability to satisfy a one-size-fits-all protocol.

In order to benefit from this built-in flexibility, the system should not be running on the bleeding edge of your battery bank's ability to charge or discharge. Given some wiggle room, an individual battery can de-rate or drop out entirely to deal with a temporary voltage imbalance or temperature issue without interrupting your evening with an unexpected blackout.

Conclusion

Sizing a battery bank above the bare minimum required to meet delivery and storage requirements comes with a bevy of benefits. Your batteries will last longer and your power availability will remain flexible in the face of suboptimal solar production. When this approach is taken with Pylontech batteries, the additional benefit of increased system health and resilience is realized through the advanced global and local functions of the BMS.

Need help sizing a battery bank for your application? Just reach out to our team here or email me directly at mike@intelligentcontrols.io.

Related Articles:

Pylontech US5000 Quick Start Guide

How Many Pylontech Batteries Can Be Connected Together?

Battery Communication: Closed vs. Open-Loop Communications

Bad, Better, Best: Battery-Inverter Communications & Compatibility

Shop LiFePO4 batteries

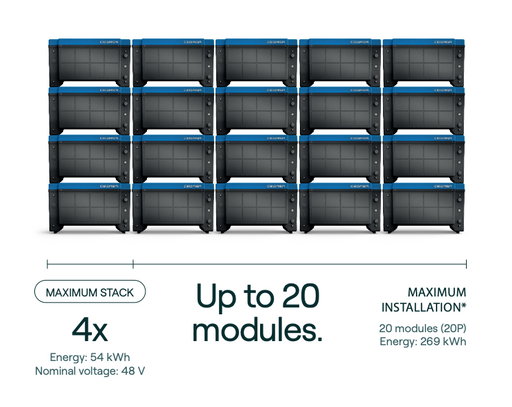

Cegasa E/Bick 48v Lithium Battery

CegasaThe 48v E/Bick LV battery by Cegasa scales to meet your energy storage needs from 13 to 269kWh. With its plug & play connections, the E/Bick i...

View full detailsPylontech US5000 48v LiFePO4 Battery

PylontechThe Pylontech US5000 offers unparalleled reliability and power delivery. This 48V rack-mount sets a standard that other form-factor lithium batteri...

View full detailsVictron Lithium NG Batteries

Victron EnergyBuilding upon the success of Victron's Lithium Smart Series, the NG (Next Generation) series incorporates significant improvements, including: Ad...

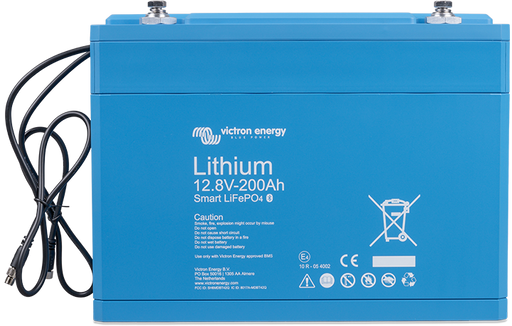

View full detailsLithium Battery 12.8V & 25.6V Smart

Victron EnergyAvailable in 12.8 and 25.6V models, Victron Energy's Smart Lithium is a robust, heavy-duty LiFePO4 battery with a high charge and discharge capacit...

View full detailsPylontech 12V LiFePO4 Battery

PylontechBring your mobile application into the 21st century and throw away your shunt with a modern, drop-in battery. Pylontech’s RT12100G31 has it all: It...

View full details