How Does the Hatz fiPMG Compare to Most Off-grid Generators?

Hatz, a German engine manufacturer, has been producing a line of compact, diesel DC generators that are just starting to be noticed in the United States. Is a DC generator an advantage in off-grid or mobile power systems? What makes them a viable option today? Are there any benefits to using a diesel generator instead of a propane generator in such applications?

How a Hatz DC Generator Works

First, let's clarify the difference between a DC generator and a traditional AC generator. In our context, DC generators share many similarities with familiar Honda or Yamaha inverter generators. Mainly, there is a 3-phase permanent magnet electrical end that is then run into an inverter connected directly to the generator. This inverter takes the 3-phase power and turns it into a new output with the exact voltage and frequency characteristics we want. The advantages of this topology are many, but the main benefit is that by decoupling the engine speed from the output using the inverter module, you can have a variable-speed engine.

The second major advantage is having extremely clean and stable power. Another method of obtaining DC power from a system like this is by using a basic rectifier circuit. With this design, the voltage of your 3-phase power will vary with RPM, and as a result, the voltage of your DC power will also vary with RPM. Your output power will have noise from the rectifier circuit, which can be filtered to some extent. However, the noise will still be present, and the stability of that voltage depends on the engine control. Even with the best controls, the voltage will not remain completely steady. This is important when you are charging a lithium battery and you want 53V not 53.2V. The main advantage of an inverter generator like the Hatz fiPMG is its extremely accurate output control.

The Propane Comparison

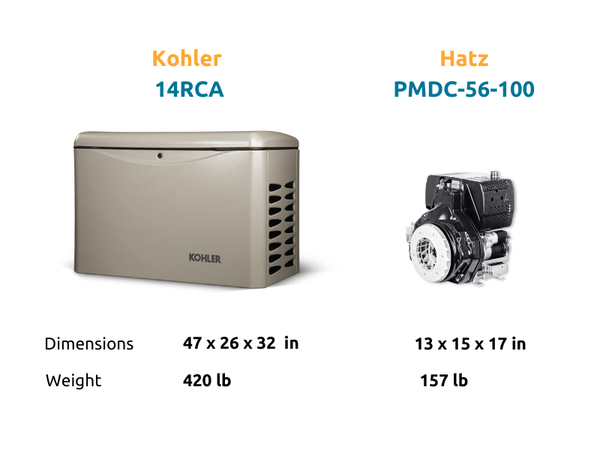

The Kohler 14kW propane generator has been the preferred choice among our off-grid customers for many years. This generator offers automatic start/stop functionality, comes at a low cost of about $6,500, and has proven to be fairly reliable. Its auto-start capability sets it apart from low-cost, portable generators. Once connected to a 1,000-gallon propane tank, it can provide fuel for an extended period of time.

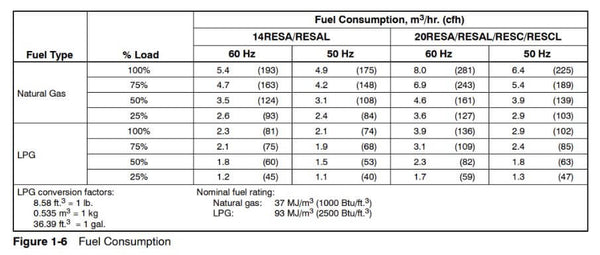

The fuel consumption rates for this generator are listed in the following table, ranging from 81 to 45 cubic feet per hour, which is equivalent to 1.2 to 2.23 gallons per hour. Considering the current propane price of approximately $2.20 per gallon, the operating costs range from $2.70 to $4.9 per hour.

Fuel Comparison Comparison of Kohler 14kW and 20kW Home Generator, Product Installation Guide, pg. 14.

How an AC Generator is Loaded in these Systems

With an AC generator, the generator takes over the house load and charges the batteries simultaneously. For a "typical" home with a 10kW inverter and household loads of about 3kw, the charger in this case would require 7kW. Therefore, a generator with a potential output of 10kw is needed. It is important to consider any surges in home loads, such as when the water pump turns on. To account for altitude deration, it is necessary to provide sufficient headroom, as not all AC generators are designed to run at full output for extended periods of time. As a general rule, altitude affects ordinarily aspirated engines by reducing output by 3% for every 1000 feet. Therefore, 6,500 feet, a 14kW generator would have lost 20% of its output, or 2730W. All to say: the generator will be operating near or potentially exceeding its design limits.

Does the propane generator described above meet your exact needs? Or do you require the larger 20kW unit on the chart above? Many system designers would probably recommend the larger unit, especially in non-Victron systems that do not offer PowerAssist. A 20kW generator will certainly not improve operating costs.

Hatz vs. Kohler

How does a Hatz fiPMG compare to the Kohler generator mentioned above?

The 6kW Hatz generator directly competes with the most common option, the 14kw Kohler generator. However, the limiting factor for charging batteries with a Kohler is actually the size of its inverter system. Assuming a 10kW inverter system as mentioned earlier, we can charge at a rate of approximately 100 to 130A. On the other hand, the Hatz 6k has a steady charge rate of 100A. Additionally, the fuel cost per gallon of diesel is around $2.90 at the pump, while off-road diesel is typically priced at $2.65, or 25 cents less.

At 3,000 feet, the Hatz engine consumes 0.6 gallons of fuel per hour when loaded and continuously outputs 100A.

That’s $2.65 * 0.6 = $1.59 per hour.

In comparison, a 14kW Kohler generator operating at 50% load consumes 1.7 gallons of fuel per hour. The current cost of fuel delivered is $2.2 per gallon.

That’s $2.2 * 1.7 = $3.75 per hour.

The inverter/charger in the Kohler system operates at 80% efficiency. The 20% loss in efficiency must be compensated by the generator. Referring to the chart above, this would require the generator to operate in the 2-gallon per hour range, increasing the operating cost to $4.4 per hour.

Setting simulations aside, we have observed significant cost savings in installations where Kohlers and other competitive brands have been replaced with a Hatz DC generator. Even with conservative estimates, it is reasonable to expect a 64% reduction in fuel costs when operating a Hatz generator. It is important to note that the purchase price for both options is quite similar.

Is a Hatz Diesel Generator Right for You?

In a Hatz generator system, this small DC generator starts automatically based on the state of charge or battery current. It charges your batteries at the same rate, or even better, than your inverter/charger, but at half the fuel cost of the most likely alternative. By communicating with a Victron GX device, the Hatz generator is controlled by the rest of the system, ensuring that the batteries receive the precise charge they require. Additionally, valuable performance metrics are automatically data-logged for future analysis and can be remotely monitored for free on Victron's remote management platform, VRM.

Major considerations for integrating a Hatz into your system design:

1. Fuel supply and consumption: Running a Hatz fiPMG generator for 2 hours will charge your battery bank with approximately 12kW. In this case, fuel consumption would be 1.7 gall/day. Transporting diesel fuel for the Hatz generator is similar to transporting fuel for your tractor. No need for delivery trucks, propane tank rentals, or professional gas fitters.

2. Maintenance and physical footprint: The Hatz generator is air-cooled, making it simple to maintain. It weighs only 157 lbs, making it easy to transport to a service center if needed. Designed for continuous duty in hot, dirty, industrial environments, the Hatz fiPMG performs well in typical off-grid applications. Hatz generators are durable, starting with high-quality components and supported by service centers throughout the United States. To provide some perspective, this Hatz engine is used in the auxiliary power unit of the Abrams Main Battle Tank, as well as in challenging applications like vibratory compactors, light towers, and asphalt pavers.

85% lighter and shorter than conventional generators, Hatz permanent magnet generators are easy to incorporate into existing system designs. Download the datasheet.

3. Cold weather starting and enclosure options: Propane generators run hotter but still require carburetor and pressure regulator heaters to reliably start in cold weather. Diesel generators, on the other hand, require glow plugs and winter fuel if left outside without any heat. With thoughtful consideration of the enclosure and a small heat source, however, a modern diesel engine will reliably start even on the coldest day.

The Hatz fiPMG is specifically designed to be integrated into a purpose-built enclosure. Rather than using stand-alone generators housed in steel or plastic shells, which can make proper ducting difficult and expensive, manufacturers have the advantage of building the most practical enclosure for their specific application, particularly in cases where space is limited.

Conclusion

For many years, the market has been laser-focused on developing products for the home standby customer, where purchase price and production time stifle quality and innovation.

This gap in the generator market has existed for along time. In fact, many of us forgot it was there! When we step back to consider desired performance, not just what’s been available historically, a Hatz generator battery charging system checks all the boxes. It’s high quality, right-sized with low operating costs, offers remote start and remote monitoring capabilities, and is affordable.

Our team has been actively involved in realizing the integration of Victron-Hatz and we have a wealth of experience with various applications. If you need guidance or design support for integrating these generators into your systems, that's exactly what we specialize in. Feel free to send us a message here or email us directly at hatz@intelligentcontrols.io.

Related:

Breaking Free from Generator-Only Power: An Intro to Hybrid Generator Systems