Remote Monitoring Capabilities of Victron-Pylontech Power Systems

Victron’s remote management tool, VRM, offers tremendous value to businesses and manufacturers leading the design, installation, and management of power systems.

While cost-savings associated with remote monitoring are staggering, especially as the number of systems monitored increases, VRM offers many layers of value that are not always recognized or appreciated.

When we talk about remote monitoring, we can’t ignore battery choice. The battery is as important as any other piece of equipment and it’s often the weakest link in any power system. If we have a non-communicating lithium in the system, we won’t be able to reap the full benefits of remote monitoring.

In this article, we’ll describe what you can see remotely in a Victron system with a communicating lithium battery and the advantages it provides to you and your customers.

Victron-Pylontech Communications

We’ve found this inverter-battery combination to work very well in off-grid and grid-connected systems of all sizes - but there are some very practical reasons for our preference for Pylontech batteries. The first is the level of remote access we have to power system installations, no matter where they are located, and how effectively we can diagnose and resolve battery-related issues if they occur. This is due to A) Pylontech’s advanced BMS and B) Victron’s DVCC function.

To learn more about the importance of battery communication in designing high-performing power systems, read Bad, Better, Best: Battery-Inverter Communications & Compatibility.

Victron GX as the Active Controller

A Pylontech battery’s BMS automatically data-logs important information, such as battery voltage, state-of-charge, min and max temperature of the cells in a module, cell imbalance, or whether a module is blocking a charge. When connected to a Victron GX device with DVCC turned on, that GX device functions as an active controller of charge and discharge parameters.

Cerbo GX as Gateway to VRM

With an internet connection and a GX device, information from critical components in the system can be pulled into VRM (check out some live demo systems here).

From the VRM portal, you can invite and share access to an installation, identifying them as an Admin, User (limited access to settings) or Technician. Technician access allows you to view all the same system-level information on VRM, open and adjust settings via the Remote Console, etc.

Over 30 different variables can be tracked from VRM. That data, logged in real-time, is stored for a year at a time and that data can be downloaded in a .CSV for long-term storage.

The system owner or end user can look at the portal to monitor real-time system performance. Otherwise, the data update is adjustable to match a limited internet connection.

Data will be stored on-site, and if the internet is lost, it will update to the cloud when the network is re-established. The Cerbo GX also features a micro-SD card slot to expand the internal data recording space to accommodate even longer periods of unconnected tracking and history.

In the Advanced tab of VRM, this otherwise overwhelming wealth of data can be visualized via simple graphics as you select the variables you care to monitor.

VRM: Tech Support Dreams Come True

VRM allows technicians to monitor the state of the batteries and troubleshoot common issues that arise. As a business that supports Victron-Pylontech systems across the country, we use VRM every day to:

-

View the real-time performance of installations at a glance.

-

Monitor the overall performance of the systems we support.

-

Create alerts based on SoC, temperature, battery status, etc, to identify issues before they become a problem.

What battery-specific data can we see? Thanks to Victron’s DVCC function, Pylontech batteries actively share critical battery health indicators with the rest of the system using the Victron GX as the gateway.

From a Victron GX Touchscreen or via VRM, we can see:

-

State of Charge

-

Battery and System Voltage

-

Min/Max Battery Cell Temperature

-

Time to Go (an estimate of the time remaining based on current loads)

-

Alerts and Alarms generated by the BMS

-

Maximum Charge/Discharge Rates

-

Current AC & DC loads

-

Input Power (Grid, generator, solar, etc)

-

Etc, etc, etc - any data point available to the system can be seen via VRM.

To review actual trends in these and other indicators, we can turn to the VRM portal on our computer or tablet.

Troubleshooting a Victron-Pylontech system

Every system can have an issue. The question is: will you know, how fast will you know, and how quickly can you resolve the issue? Of course, that depends on the quality and accuracy of the information you have from the source - the system itself.

Here are a few examples of the types of issues that can be recognized and resolved in a Victron-Pylontech system:

Scenario 1: The battery is out of balance

When a system has too large of a voltage difference between two individual batteries, that usually indicates that one battery had a reason to isolate itself from the system. This could be due to a number of causes; a battery became too hot or too cold, it reached a voltage which is too high, or a low voltage, etc. Regardless of the situation, a communicating battery should be able to work with the other batteries in the bank to rebalance the system. Any Pylontech battery will actively conduct balancing during a charge or discharge cycle, reaching a state of balance and continuing to operate per normal - often this is done without the user even realizing it’s happened.

If there’s a large voltage difference between two cells in the same battery, this is usually an indication of a more critical issue. A small difference of a few hundredths of a volt (or a few tenths of a volt in lower-quality batteries) is often observed during charge and discharge. This difference should balance out once the charge/discharge slows and the battery returns to more of an idle state. If there is a persistently high or low cell in your system it may be an indication that a cell is failing. A Pylontech battery, via VRM and the Remote Console, tracks this high/low cell voltage state. If a battery bank consistently has a battery with a low cell voltage it can be an early indicator of a failing cell, or a cell that is sitting close to a cold wall and is having a harder time charging, etc.

Scenario 2: The battery is experiencing low voltage

A battery with a very low voltage is often a result of insufficient charge. A communicating battery can help you identify if the charge issue is a result of insufficient charge sources like solar or a grid/shore power connection, or if the battery itself is restricting charge. We often troubleshoot non-Pylontech systems where a system shutdown happens much earlier, or at a much higher voltage than expected. After much effort and more extreme bench testing, it’s quite possible to discover that the non-communicating battery BMS is providing a useful protection and is shutting down the battery early because of a failing cell - however, it’s hard to know this without taking the installation and the battery apart. In a Pylontech battery system that is sharing its high-low cell voltage data, this can be recognized remotely, without ever touching the battery.

Scenario 3: The battery is experiencing high voltage and has isolated itself

This scenario can be similar to a low voltage situation and may be the result of a cell holding insufficient charge and reaching a high voltage before the rest of the cells in your battery bank, triggering that battery BMS to isolate the battery and thereby changing the nature of your bank - possibly resulting in the system becoming “full” according to voltage before the SOC or system voltage has reached 100%.

Alternatively, this can be an indication that some component in your installation is charging at a voltage higher than the battery wants. We see this most often in systems with old charge controllers for things like wind and hydro, and occasionally with old inverters or solar chargers.

How do you tell the difference? Is the whole bank reaching that high voltage, or just a single battery or cell? With a non-communicating battery, this is nearly impossible to determine without extensive time on site.

Scenario 4: The battery got too cold or too hot

A common method of measuring a battery's temperature is to take a sensor reading at the lug of the battery. In many cases, particularly with lithium, the cells themselves will generate some heat and your measurement on the exterior of the battery can be ±10°F different from the internal cell temperatures. A Pylontech battery monitors internal temperatures at the cell level as a secondary indicator of something going wrong with a cell - a single cell that is consistently higher in temp is an early warning sign that there may be a more critical failure imminent, or that there is something specifically needing fixed in the physical installation (such as one side of a battery too close to a heat source like a generator exhaust line). When working with systems in hotter or colder climates this temperature difference can mean a lot when it comes to efficiently heating and cooling your system.

Scenario 5: The battery has shut itself off

This is one of the biggest challenges to troubleshoot when working with a non-communicating battery. Did the battery shut off because it’s broken? Did it shut off because it got too cold or too full? Is your charge source causing issues? If you can see what happened inside of the battery before the shutdown you'll probably be able to determine what happened, or at least you have an indication of what happened. For example, knowing a battery was full and limiting charge for a couple of hours before isolating itself is a great indicator of a charge source having a charge voltage set too high.

VRM: Better Than Being Onsite

What is the value of VRM to manufacturers, installers, or end users? As you can imagine, there are many! Let’s run through a few obvious ones:

Value #1: Remote Access to Installed Equipment, Data Logs & Device Settings

The value of being able to push a firmware update on 100 installations or to adjust a setting to a single component without making a site visit cannot be understated. We work with hundreds of small to large businesses that are taking advantage of Victron’s remote monitoring capabilities to scale business. When you’re able to solve a problem for a customer before they knew it was a problem, you save money, win trust, and win future contracts.

Value #2: Provide Effective Technical Support

When your customers do experience an issue and they're not sure what to do about it, they’re not alone, even if they are hundreds or thousands of miles away from ‘tech support guy.’ If the system is already shared with you on VRM, it takes a few minutes to access months of data, making it better than being onsite, and waiting for the error to re-occur. With VRM, your ability to quickly identify, resolve, or provide helpful next steps on issues has been vastly improved.

Value #3: Optimize System Performance Over Time

The ability to actively monitor and adjust system settings helps us to ensure optimal performance over years of operation.

VRM was originally designed for managing fleets. Say you’re a manufacturer building 100 hybrid generator systems a year and renting them out for use on construction job sites. In 5 years, you have 500 systems out working in the field across 6 states.

From your VRM Dashboard, you can sort and view all the systems you are responsible for managing and apply tags that help you sort and view them according to customer or according to geographical location. You have a very unique, global perspective on a group of systems that you built and want to make better over time. That might be adding battery capacity, adding or removing insulation from the battery enclosure, adding another solar array to your design, etc. There’s no better way to get that feedback and, in turn, make evidence-based decisions that improve system performance than with remote monitoring.

Value #4: Peace of mind

Everyone wants to know “Is the system I built working?” “Are the batteries balanced?” As part of the commissioning process, the installer will connect the system to VRM, add the Pylontech batteries to the device list, and confirm that yes, all 8 batteries are online and reporting their SoC. He can set alerts on minimum voltage or battery temp to identify potential issues before they become a problem of concern. You’d never start a road trip without referencing your tank meter. We all expect reliable, accurate data for decision-making, right now and right in our pocket. How amazing that Victron has made VRM (which is costly to support) free for us as users. What a value!

Conclusion

We often say that when Victron inverters and Pylontech batteries come together in a system, the result is essentially a whole new product with layers of features and benefits to the user that are only realized and made available when combined together. How can your Victron power systems start benefiting from this 'third data sheet'? Reach out to our team or contact me directly at reid@intelligentcontrols.io to learn more or to start integrating Pylontech batteries into your Victron power systems.

Related Articles:

Pylontech US5000 Quick Start Guide

How Many Pylontech Batteries Can Be Connected Together?

Battery Communication: Closed vs. Open-Loop Communications

Bad, Better, Best: Battery-Inverter Communications & Compatibility

Shop LiFePO4 batteries

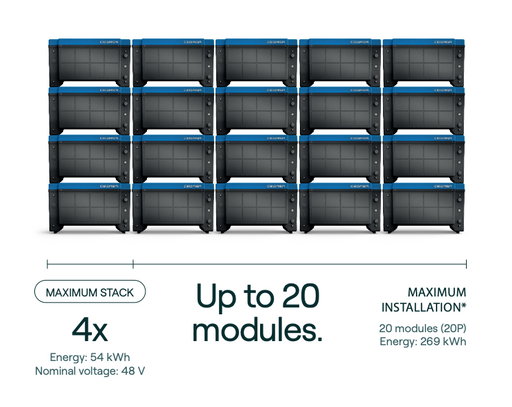

Cegasa E/Bick 48v Lithium Battery

CegasaThe 48v E/Bick LV battery by Cegasa scales to meet your energy storage needs from 13 to 269kWh. With its plug & play connections, the E/Bick i...

View full detailsPylontech US5000 48v LiFePO4 Battery

PylontechThe Pylontech US5000 offers unparalleled reliability and power delivery. This 48V rack-mount sets a standard that other form-factor lithium batteri...

View full detailsVictron Lithium NG Batteries

Victron EnergyBuilding upon the success of Victron's Lithium Smart Series, the NG (Next Generation) series incorporates significant improvements, including: Ad...

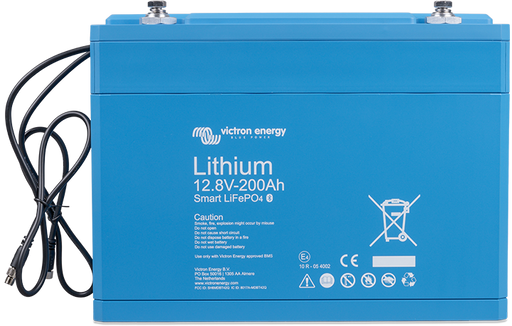

View full detailsLithium Battery 12.8V & 25.6V Smart

Victron EnergyAvailable in 12.8 and 25.6V models, Victron Energy's Smart Lithium is a robust, heavy-duty LiFePO4 battery with a high charge and discharge capacit...

View full detailsPylontech 12V LiFePO4 Battery

PylontechBring your mobile application into the 21st century and throw away your shunt with a modern, drop-in battery. Pylontech’s RT12100G31 has it all: It...

View full details